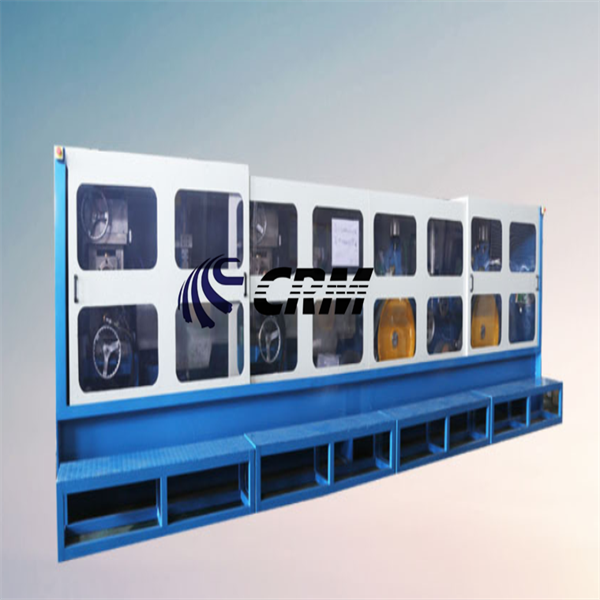

Flat Wire Production Line for Spring Steel Wires

Flat Wire production line for spring steel wires, as known as flat wire rolling mill, flat wire drawing machine or wire flattening mill is made by feeding rod of the appropriate diameter through our High precision rolling mill, where it is flattened to the desired thickness and width. A set of opposing rolls in the other direction achieves the correct width and forms the edge, whether round square, sharp edge or some special shape. Our flat wire production line are the first choice when it comes to the production of narrow but resilient products for manufacturing. Such things as zippers or wiper blades, which, despite their small size, are consistently expected to perform. The advantages: With flat wire production line we are able to produce long running lengths without welded seams, and the edge shapes of our products can be designed as desired. Our entire flat wire rolling mill production line can reach 400 meters/minute.

Description

Flat Wire Production Line for Spring Steel Wires | |

Brand | CRM |

Model | CRM-2024-89877 |

Line Speed | 30-350 m/Min |

Type | Precision Cold Rolling |

Input Material Details | |

Material Grade | Spring Steel Wires |

Input Diameter | Customized |

Tolerance | +-0.001mm or can be Customized |

Stages | Single stage/Tandem wire flattening& shaping lines |

Output Material Details | |

Shapes | Flat shapes, Deburred |

Output range | Thicknesses in mm, 0.15 – 8mm Width in mm, 1 – 30mm |

Finishes | Rolled, Annealed, Hardened and tempered |

Wire Takeups | |

Widths | from 10mm |

Inner Diameter | 400-500mm |

Outer Diameter | max. 1,350 |

Oscillated Wound Coils | |

Inner Diameter | 400 – 500mm |

Outer Diameter | max. 1,200 |

Coil Width | 80 - 550 |

Coil Weight | max. 2,700 |

We Feature a Wide Range Of Flat Wire Production Lines

Flat Wire production line for spring steel wires, as known as flat wire rolling mill, flat wire drawing machine or wire flattening mill is made by feeding rod of the appropriate diameter through our High precision rolling mill, where it is flattened to the desired thickness and width. A set of opposing rolls in the other direction achieves the correct width and forms the edge, whether round square, sharp edge or some special shape. Our flat wire production line are the first choice when it comes to the production of narrow but resilient products for manufacturing. Such things as zippers or wiper blades, which, despite their small size, are consistently expected to perform. The advantages: With flat wire production line we are able to produce long running lengths without welded seams, and the edge shapes of our products can be designed as desired. Our entire flat wire rolling mill production line can reach 400 meters/minute.

Application For Spring Steel Flat Wire Production Lines

Cold-rolled metal spring steel flat wire production lines finds extensive application in spring steel wire due to its specific properties and characteristics that are essential for manufacturing high-quality spring steel wire. Here’s a comprehensive overview of the application of cold-rolled metal flat wire in spring steel wire:

1. The Wiper blades can be made from our flat wire production and it can be used for automotive applications

In a windshield wiper's rubber profile, a spring rail made of flat wire production line inconspicuously enhances safety-slightly bent and under tension, it presses the rubber profile onto the windshield. Rolled from wire with robust natural edges, the material offers high strength and bending uniformity. If you are a manufacturer of door and window accessories, our precision flat wire rolling mill will be your best choice, because the finished products produced by our rolling mill can meet all your requirements

2. Highly resilient flat wire production line used for Timing chains for automotive applications

The spring steel flat wire production used for timing chains in motors must meet both of these requirements. Flat wire production line from sky bluer are ideally suited for this purpose. Rolled from wire and hardened and tempered using the flash martensite process, This spring steel flat wire production line will be your best choice

3. Application of steel flat wire in automobile balance weights

Sky bluer Spring steel flat wire production line is utilized in several automotive applications, including the production of balance weights. Our spring steel flat wire offers a cost-effective solution for manufacturing balance weights, providing a balance between material cost and performance.

Customized edge shape