Wire Rolling Cassettes

our company has invented a new type of cassette roller die, which includes at least 2 wire blank roll dies and at least 2 wire feed blank roll dies. It is composed of a rhombus and a rhombus, the circular structure is located in the middle, and its two sides are composed of the rhombus of the rhombus structure. When the strength is lower than 160N/mm2, the drawing of zinc and its alloy wires can achieve the characteristics of zero width and elongation of more than 30%, so as to improve the efficiency of the roll die technology applied to the drawing and diameter reduction of zinc and its alloys, and the The stability of the drawing process has the advantages of stable and difficult to turn over during the rolling process of the wire blank and high deformation rate.

Description

wire rolling cassettes

Product Details:

wire rolling cassettes Price And Quantity

Minimum Order Quantity 1 Set

wire rolling cassettes Trade Information

FOB Port Shanghai,China

Payment Terms Letter of Credit (L/C) Telegraphic Transfer (T/T)

Supply Ability 1 Set Per Day

Delivery Time 20 Days

Sample Policy Contact us for information regarding our sample policy

Product Description

what is wire rolling cassette?

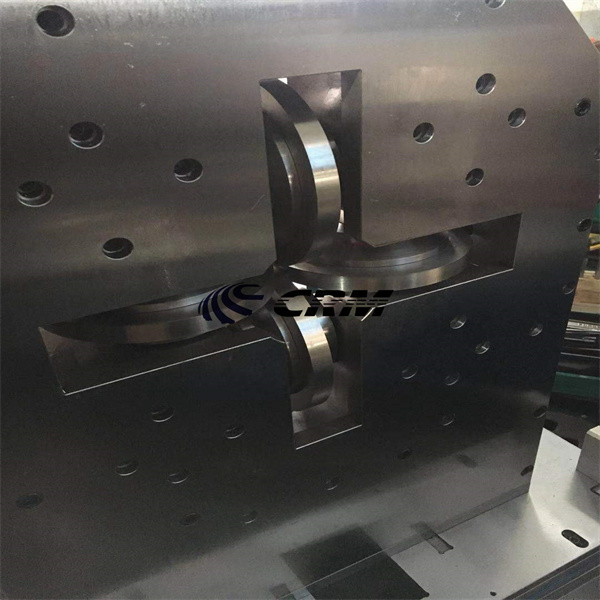

wire rolling cassette, referred to as cassette roller dies, roll die, is a drawing die, is a kind of wire drawing/roller die, mainly used in metal processing.

The die hole of the roller die consists of several rolling rollers. The structure of the roll die has two rolls, three rolls, and four rolls. According to the number of die holes in a roll die, there are single-module, two-connected, three-connected, four-connected and so on. The roll die has a history of nearly 100 years, and is currently mainly used in the drawing of cold drawn steel bars, various solid steel wires and flux-cored welding wires. The life of the roller die is generally 3000 tons to 5000 tons, and it can continue to be used after maintenance. No lubricating powder is required for the roll die drawing process. The support shaft of the roller in the roller die adopts an eccentric shaft structure, and the hole pattern can be adjusted. In the detection of the shape and size of the die hole of the roll die, a microscope and an image measuring instrument are used to enlarge the die hole and then detect it. There are two ways to lubricate the bearings of the roller die: lubricating oil and grease. The cooling of the roll die is cooled by cooling water or lubricating oil.

our company has invented a new type of cassette roller die, which includes at least 2 wire blank roll dies and at least 2 wire feed blank roll dies. It is composed of a rhombus and a rhombus, the circular structure is located in the middle, and its two sides are composed of the rhombus of the rhombus structure. When the strength is lower than 160N/mm2, the drawing of zinc and its alloy wires can achieve the characteristics of zero width and elongation of more than 30%, so as to improve the efficiency of the roll die technology applied to the drawing and diameter reduction of zinc and its alloys, and the The stability of the drawing process has the advantages of stable and difficult to turn over during the rolling process of the wire blank and high deformation rate.