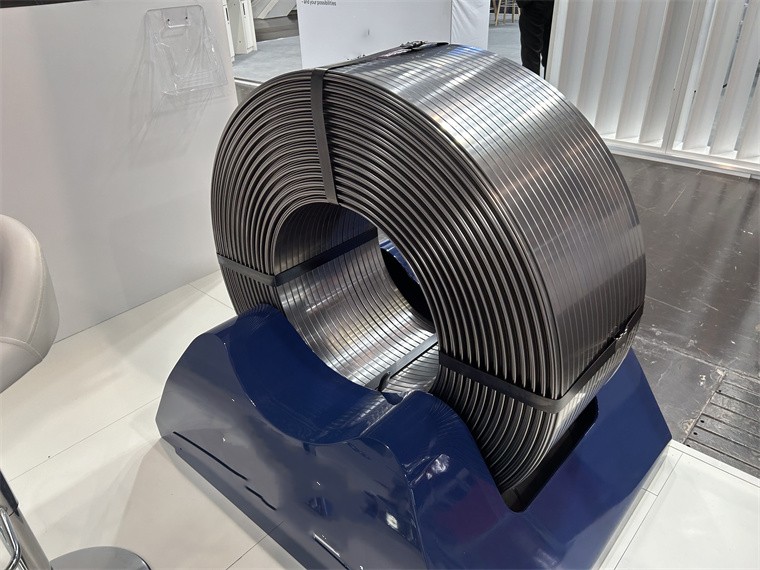

2 Hi Rolling Mill for produce flat and square wires

This is a forming process in which material is passed between two or more rotating tools (rollers). During longitudinal rolling, the rolling stock is moved at an angle perpendicular to the rolling axes, without rotating around its own longitudinal axis, and travels down the gap between the rollers.The finished products are suitable for electromagnetic wire, petrochemical industry, paper making, screen, DFL, car, motorcycle, aviation, war industry and so on.Using the most advanced control system and monitoring system, tracking and automatically adjust the product quality and technical parameter. Take-up adopts precision rewinding and winding system.

Description

2 Hi Rolling Mill

Product Details:

Type Cold Rolling Mill

Material high accuracy rolling from round and flat wires into flat&shaped ss wire,carbon steel wire,alloy wire

Capacity 50 Ton/day

Computerized Yes

Automatic Grade Automatic

Control System PLC Control

Voltage 380-440 Volt (v)

Share Your Product:

2 Hi Rolling Mill Price And Quantity

Price 6000 USD ($)/Piece

Minimum Order Quantity 1 Paint

Price Range 6000.00 - 10000.00 USD ($)/Piece

2 Hi Rolling Mill Product Specifications

Control System PLC Control

Capacity 50 Ton/day

Voltage 380-440 Volt (v)

Automatic Grade Automatic

Computerized Yes

Material high accuracy rolling from round and flat wires into flat&shaped ss wire,carbon steel wire,alloy wire

Type Cold Rolling Mill

Warranty 1 year

2 Hi Rolling Mill Trade Information

FOB Port shanghai

Payment Terms Telegraphic Transfer (T/T) Letter of Credit (L/C)

Supply Ability 10 Paint Per Month

Delivery Time 2 Months

Sample Policy Contact us for information regarding our sample policy

Main Export Market(s) Western Europe Asia

Certifications ISO

Product Description

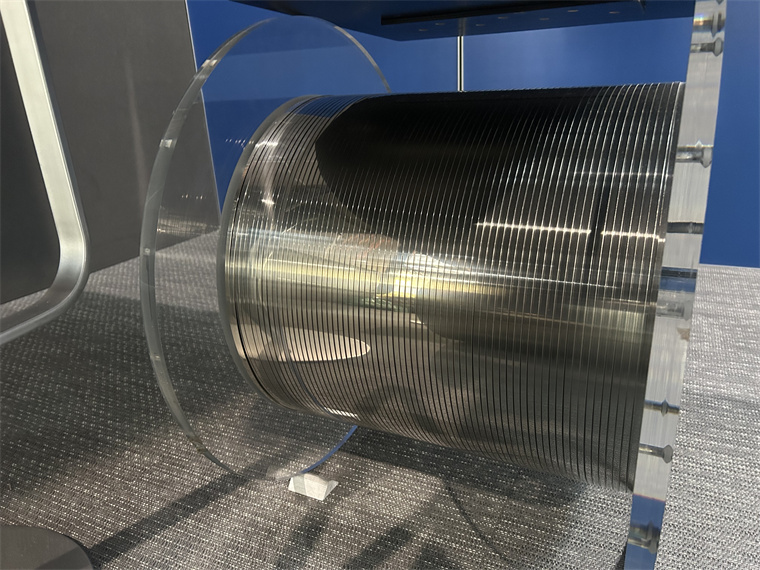

Precision rolling machine The machine is suitable for rolling all kinds of flat or shaped wire, copper,Aluminum, stainless steel, carton steel, high speed steel, alloy wire.

Our 2 Hi rolling mill or 4 Hi rolling mill is applied for rolling different type flat & shaped wire. Running by advanced control system and monitoring system, machine can directly show the speed and real-time rolling size data. Laser measurement combines with closed looped control helps stabilize the production, ensure high precision rolling.

Features

This is a forming process in which material is passed between two or more rotating tools (rollers). During longitudinal rolling, the rolling stock is moved at an angle perpendicular to the rolling axes, without rotating around its own longitudinal axis, and travels down the gap between the rollers.The finished products are suitable for electromagnetic wire, petrochemical industry, paper making, screen, DFL, car, motorcycle, aviation, war industry and so on.Using the most advanced control system and monitoring system, tracking and automatically adjust the product quality and technical parameter. Take-up adopts precision rewinding and winding system.

Uses: used in tool steel or high-speed profiled wires, centrifuge sieves, heat exchanger, ski steel edges, piston rings, oil rings, etc.; PV ribbon, Enameled rectangular wire, precious metal composite material, high-speed rail sliding wire, gold and silver coin billet belt (mint), flat wire, steel belt, copper belt, copper foil, etc.

Applying materials: suitable for high-carbon, medium-carbon, low-carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire, copper aluminum wire,

brass wire and other non-ferrous and ferrous.

Roll material:tool steel, sintered metal or carbide steel, alloy steel.

Roll diameter: 90-450mm

Roll accuracy: less than 0.001mm

Power system: Servo motor or three-phase motor

Press-down mode: electric or manual

Optional devices: guide wire device, roll force meas

About Company

Sky Bluer Environmental Technology Co. Ltd ismanufacture specialized in high precision cold wire rolling mills and systemsfor metal shaping, which mainly includes micro precision cold rollingmills,wire strips rolling mills,precision wire rolling mills,cold rolled mills,cassette roller dies, Turks head dies, wire flattening mills, universal rollingmills, PV rolling machine and Tin coating production and precision rolling millrollers for flat and shaped wires. We have independently R&D rectangularspring wire mill, flat wire rolling mill, volute spiral spring tandem rollingmill line, and triangular wire rolling mill to replace brandEurope/USA/Japan cold rolling mills.

By the new method of Self-made cold rolling millcombined with drawing rolling die, our concept will be adjusted to this newmethod it guarantees for the most cost-saving quality improvement of yourproducts. better quality in evenness and finishing, the straightness up to0.5mm/m, thickness and width tolerance can be accurate down to within 0.005mm.Active introduction of Brand Japan small high-precision roll processing andgrinding technology, the roundness tolerance is less than 0.001mm., finishingis 0.02m.

Service Commitment: What we provide is not onlyequipment, but also technology and service. We provide users withfree-of-charge for shaped wire proofing and hole design.

Contact us: www.precision-rolls.com info@precision-rolls.com whatsapp:0086 13861313954