Best Strip Rolling Mill Manufacturer

used to produce triangular wire and wedge wire for stainless steel screenmesh.Applying material: stainless steel wire (202, 205, 304, 304L, 316, 316L,309, 321, imported high strength material, etc.) and other materials .

Description

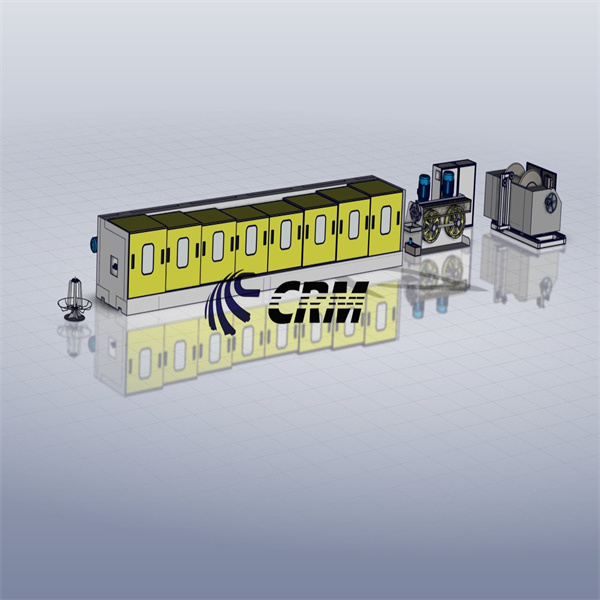

Strip Rolling Mill

Product Details:

Share Your Product:

Strip Rolling Mill Price And Quantity

Price 300 USD ($)/Piece

Minimum Order Quantity 1 Piece

Price Range 300.00 - 500.00 USD ($)/Piece

Product Description

Uses: usedto produce triangular wire and wedge wire for stainless steel screenmesh.Applying material: stainless steel wire (202, 205, 304, 304L, 316, 316L,309, 321, imported high strength material, etc.) and other materials .

Tolerancemeasurement: equipped with online measuring instrument, real-time monitoring ofthickness, width and automatic feedback to achieve closed-loop control

areen liquid,Petroleum, chemical, metallurgy, mining, pharmaceutical purification, drillingfluid purification, etc. also can be customized. es: used to producetriangular wire and wedge wire for stainless steel screen mesh.Applyingmaterial: stainless steel wire (202, 205, 304, 304L, 316, 316L, 309, 321,imported high strength material, etc.) and other materials .

Tolerance measurement: equipped with online measuring instrument, real-timemonitoring of thickness, width and automatic feedback to achieve closed-loopcontrol

item | value |

Brand Name | CRM |

Type | Cold Rolling Mill |

Condition | New |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2020 |

Warranty of core components | 3 years |

Core Components | Bearing, Gearbox, Gear |

Voltage | 380V |

Power | 37 |

Dimension(L*W*H) | 20m*5m*2m |

Weight | 20tons

|

Certification | ISO |

Warranty | 12 Months |

Key Selling Points | High-accuracy |

Showroom Location | None |

Applicable Industries | Machinery Repair Shops, Manufacturing Plant |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Local Service Location | None |

Offersdifferent rollers diameters and variable number of horizontal and vertical rollstands

Offers a complete range of:

Dancer accumulators

Pay-off

Take-up spoolers

Precise wire tension allows full control of the productss exact spreading

Vertical roll stands can be used to achieve special shapes and strongtolerances on width.

Up-to-date control technology

ensures continuous production in consistently high quality

Sky Bluer Environmental Technology Co.Ltd is manufacture specialized in high precision cold rolling millsand systems for metal shaping, which mainly includes micro precisioncold rolling mills, cassette roller dies, Turks head dies, Turk heads,wire flattening mills, universal rolling mills, and precision rolling millrollers for flat and shaped wires. We have independently R&D rectangularspring wire mill, flat wire rolling mill, volute spiral spring tandem rollingmill line, valve spring rolling mill, and triangular wire rolling mill toreplace brand Europe/USA/Japan cold rolling mills.

By the new method of Self-made cold rolling mill combined with drawing rollingdie, our concept will be adjusted to this new method it guarantees for the mostcost-saving quality improvement of your products. better quality in evennessand finishing, the straightness up to 0.5mm/m, thickness and width tolerancecan be accurate down to within 0.005mm. Active introduction of Brand Japansmall high-precision roll processing and grinding technology, the roundnesstolerance is less than 0.001mm., finishing is 0.02

Service Commitment: What we provide is not only equipment, but also technology and service. We provide users with free-of-charge for shaped wire proofing andhole design.