Cold Rolling Mill For Flat And Shaped Wires Rolling

Applying material: used to roll rectangular and squire wires, Suitable for non-ferrous and ferrous metals such as high, middle carbon steel wire, stainless steel wire, copper, aluminum and alloys.

Only one set of standard roller is needed, possibilty of roller non-replacing when forming profiled wires.

Description

Cold Rolling Mill For Flat And Shaped Wires Rolling

Product Details:

Type Cold Rolling Mill

Material ss wire,carbon steel wire,alloy wire

Computerized Yes

Automatic Grade Automatic

Control System PLC Control

Power Milliampere (mA)

Cold Rolling Mill For Flat And Shaped Wires Rolling Price And Quantity

Minimum Order Quantity 1 Set

Price 3500 USD ($)/Set

Price Range 3500.00 - 6000.00 USD ($)/Set

Cold Rolling Mill For Flat And Shaped Wires Rolling Product Specifications

Control System PLC Control

Computerized Yes

Material ss wire,carbon steel wire,alloy wire

Power Milliampere (mA)

Type Cold Rolling Mill

Automatic Grade Automatic

Cold Rolling Mill For Flat And Shaped Wires Rolling Trade Information

FOB Port shanghai

Payment Terms Telegraphic Transfer (T/T) Letter of Credit (L/C)

Supply Ability 25 Set Per Year

Delivery Time 2 Months

Sample Policy Contact us for information regarding our sample policy

Packaging Details standard packages

Certifications iso

Product Description

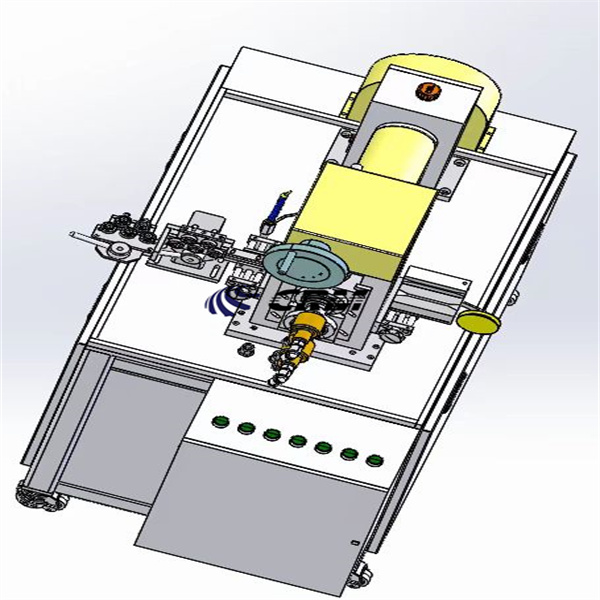

Cold Rolling Mill For Flat And Shaped Wires Rolling/wire reduction mill

Precision rolling mill stand

Square wire rolling production line parts

Profile wire rolling production line

Applying material: used to roll rectangular and squire wires, Suitable for non-ferrous and ferrous metals such as high, middle carbon steel wire, stainless steel wire, copper, aluminum and alloys.

Only one set of standard roller is needed, possibilty of roller non-replacing when forming profiled wires.

Attributes: 2 motors

Advantages: Its working life is productive than the profiled dies so that improving efficiency, saving cost and could change the polishing technology for user.

It can be operated without lubricating oil (dry operation) in a special case.

Roll material: tool steel, sintered metal or carbide steel.

Uses method: universal rolling mill

Optional devices: guide wire device, rolling force measurement system, central lubrication system, etc.