CRM DGZ Profile Wire Rolling Mill Production Line

The Shaped Wire Rolling Mill Line is made available by us in various types and designs as per the need. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The process of rolling is mainly used for either ferrous or nonferrous metal stock and is classified into cold, warm, and hot rolling of wire or sheet. The offered Shaped Wire Rolling Mill Line is very efficient and useful.

Description

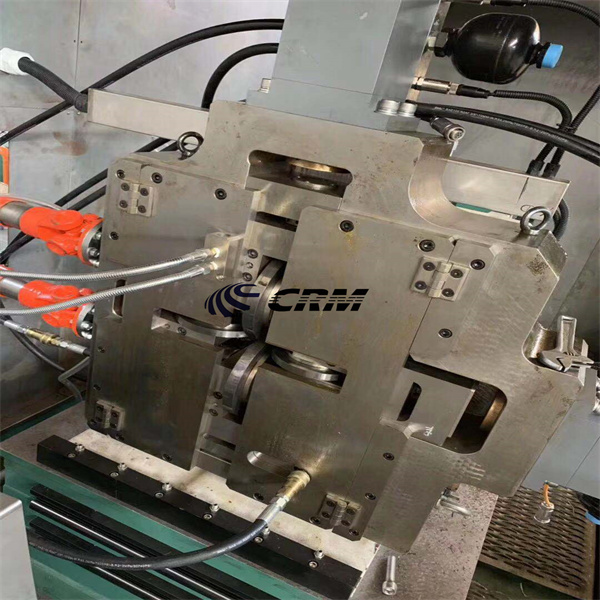

CRM DGZ Profile Wire Rolling Mill Production Line

The Shaped Wire Rolling Mill Line is made available by us in various types and designs as per the need. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The process of rolling is mainly used for either ferrous or nonferrous metal stock and is classified into cold, warm, and hot rolling of wire or sheet. The offered Shaped Wire Rolling Mill Line is very efficient and useful.

Product Details:

Type Cold Rolling Mill

Material high carbon and stainless steel wires,spring steels and etc

Capacity 100 Ton/day

Computerized Yes

Automatic Grade Automatic

Control System PLC Control

Voltage 380-500 Watt (w)

CRM DGZ profile wire rolling mill production line Price And Quantity

Price Range 6000.00 - 10000.00 USD ($)/Set

Minimum Order Quantity 1 Set

Price 6000 USD ($)/Set

CRM DGZ profile wire rolling mill production line Product Specifications

Material high carbon and stainless steel wires,spring steels and etc

Type Cold Rolling Mill

Warranty 1 year

Computerized Yes

Power 125 Watt (w)

Capacity 100 Ton/day

Automatic Grade Automatic

Voltage 380-500 Watt (w)

Control System PLC Control

CRM DGZ profile wire rolling mill production line Trade Information

Payment Terms Letter of Credit (L/C) Telegraphic Transfer (T/T)

Product Description

DGZ Series Counter-axis Four-high Flat wire Universal Rolling Mill/shaped wire Turk Head assembly machine production line/Universal Rolling Mill for making preicison wires

Uses: It is possible to perform high precision flat& shaped wires rolling experiments from round inlet wires or profile wires

Always used for rolling flat wire, square wire, rectangular and other profile wires.

process: shapes can be cold-rolled if the cross-section is relatively uniform and the transverse dimension is relatively small. Cold rolling shapes requires a series of shaping operations, usually along the lines of sizing, breakdown, roughing, semi-roughing, semi-finishing, and finishing.

Cold rolling process occurs with the metal below its recrystallization temperature (usually at room temperature), which increases the strength via strain hardeningup to 20%. It also improves the surface finish and holds tighter tolerances. Commonly cold-rolled products include flat wires, flat strips, triangular wire, wedge wires, half-round wire and etc.

Quality parts

Our precision wire rolling mill parts are made from high-quality materials using rigorously-tested manufacturing techniques. Parts are designed based on customer feedback. We consistently work to improve designs to help maximize part life.

This technology remains the industry Germany and Japan standard with its numerous precisions. Contact us today to ask our experts how we can optimize your wire rolling program.

Hot Tags: 4 hi universal rolling mill, flat wire rolling mill machine,special-shaped wire rolling machine,Germany quality,Japan technology,Usa ,Iltaly,China, suppliers, manufacturers, factory, price, pricelist, cost, for sale