Pentagonal Wire Rolling Mill

This is a forming process in whichmaterial is passed between two or more rotating tools (alloy rollers). Duringlongitudinal rolling, the rolling stock is moved at an angle perpendicular tothe rolling axes, without rotating around its own longitudinal axis, andtravels down the gap between the rollers.The finished products are suitable forelectromagnetic wire, petrochemical industry, paper making, screen, DFL, car,motorcycle, aviation, war industry and so on.Using the most advanced controlsystem and monitoring system, tracking and automatically adjust the productquality and technical parameter. Take-up adopts precision rewinding and windingsystem help you get the best profile wires in the world.

Description

Pentagonal Wire Rolling Mill

Product Details:

Type Cold Rolling Mill

Material high accuracy rolling from round and flat wires into flat&shaped ss wire,carbon steel wire,alloy wire

Capacity 50 Ton/day

Computerized Yes

Automatic Grade Automatic

Control System PLC Control

Voltage 380 Volt (v)

Pentagonal Wire Rolling Mill Price And Quantity

Price 6000 USD ($)/Piece

Minimum Order Quantity 1 Set

Price Range 6000.00 - 10000.00 USD ($)/Piece

Pentagonal Wire Rolling Mill Product Specifications

Warranty 1 year

Capacity 50 Ton/day

Material high accuracy rolling from round and flat wires into flat&shaped ss wire,carbon steel wire,alloy wire

Computerized Yes

Control System PLC Control

Automatic Grade Automatic

Voltage 380 Volt (v)

Type Cold Rolling Mill

Pentagonal Wire Rolling Mill Trade Information

FOB Port shanghai

Payment Terms Letter of Credit (L/C) Telegraphic Transfer (T/T)

Supply Ability 10 Set Per Week

Delivery Time 2 Months

Sample Policy Contact us for information regarding our sample policy

Main Export Market(s) Australia North America Central America Asia

Certifications ISO

Product Description

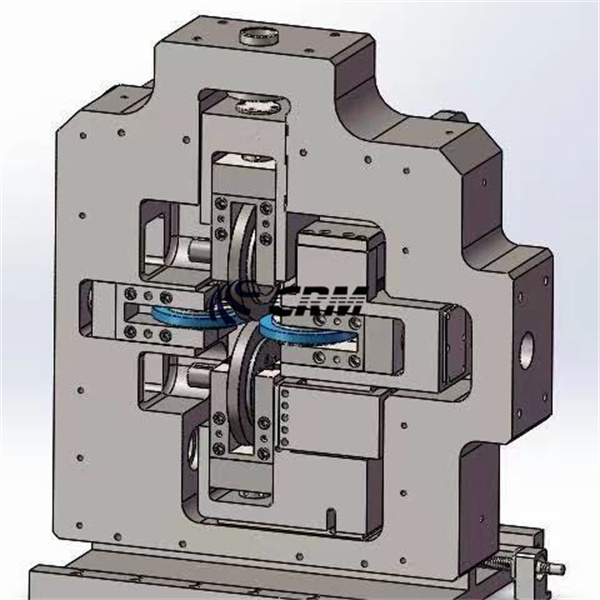

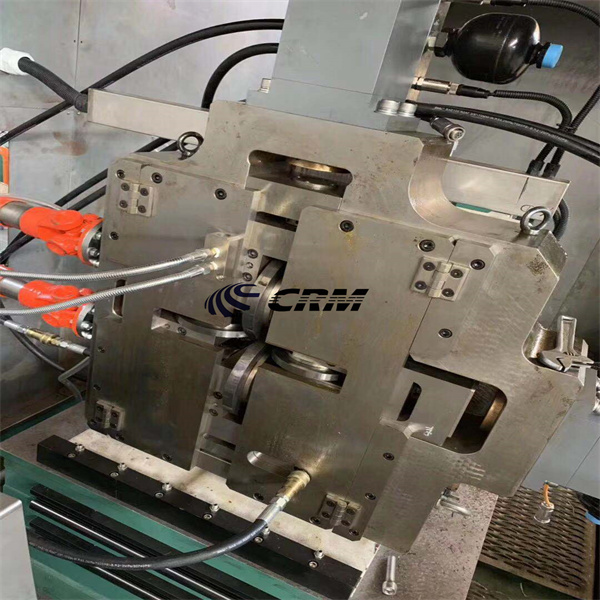

Pentagonal wire tandem rolling millline/profile wire rolling mill machine Japan stype

It is possible to perform high precisionPentagonal line wire rolling from round inlet wires.

Features:

1.We can improve the design according tothe needs of different customers

Uses: used for not rolling triangular wire,square wires, rectangular but also Wedge wire, pentagonal wires, hexagonalwires, semicircular wires, Trapezoidal wire and Pentagonal wires

2.Application industry: oil screen, coalwashing screen, environmental protection engineering, engine piston rings, diesprings, locks, clutches, medical equipment, pneumatic tools, glasses parts,handlebars, watch bands, electrical parts, clothing mechanical parts, etc...

3. This is a forming process in whichmaterial is passed between two or more rotating tools (alloy rollers). Duringlongitudinal rolling, the rolling stock is moved at an angle perpendicular tothe rolling axes, without rotating around its own longitudinal axis, andtravels down the gap between the rollers.The finished products are suitable forelectromagnetic wire, petrochemical industry, paper making, screen, DFL, car,motorcycle, aviation, war industry and so on.Using the most advanced controlsystem and monitoring system, tracking and automatically adjust the productquality and technical parameter. Take-up adopts precision rewinding and windingsystem help you get the best profile wires in the world.

4.high accuracy.