Standard Undriven Turks Head Wedge Wire Rolling Machine

A Turk Head For Shaped Wires is the most cost effective way to produce deformed or shaped wire is to use a descaler, Turks head and wire drawer in combination. The Turk's-Head is a tubular knot that is usually made around a cylindrical object, such as a rope, a stanchion, or a rail. The name refers to a general family of knots, not an individual knot. While this knot is typically made around a cylinder, it can also be formed into a flat, mat-like shape. The offered Turk Head For Shaped Wires is made for commercial applications.

Description

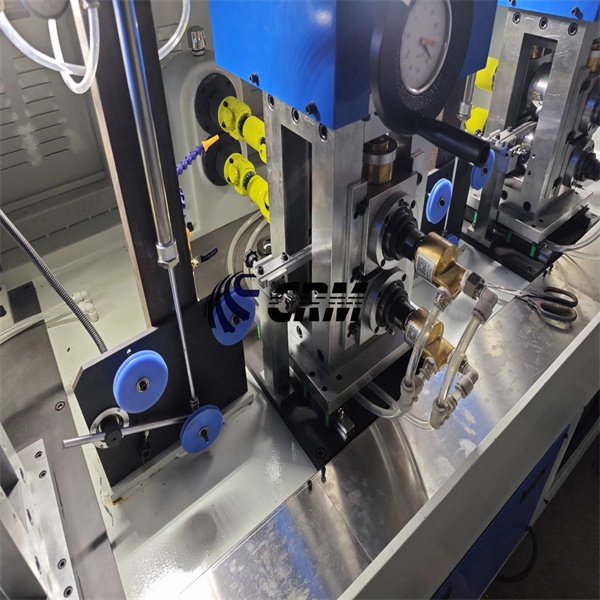

Standard Undriven Turks Head Wedge Wire Rolling Machine

A Turk Head For Shaped Wires is the most cost effective way to produce deformed or shaped wire is to use a descaler, Turks head and wire drawer in combination. The Turk's-Head is a tubular knot that is usually made around a cylindrical object, such as a rope, a stanchion, or a rail. The name refers to a general family of knots, not an individual knot. While this knot is typically made around a cylinder, it can also be formed into a flat, mat-like shape. The offered Turk Head For Shaped Wires is made for commercial applications.

Product Details:

Type Cold Rolling Mill

Material rolling from round wires into flat&shaped ss wire,carbon steel wire,alloy wire

Capacity 5 Ton/day

Computerized Yes

Automatic Grade Automatic

Control System Frequency Speed Control

Voltage 380-440 Watt (w)

Standard Undriven Turks Head Wedge Wire Rolling Machine Price And Quantity

Price Range 6000.00 - 10000.00 USD ($)/Piece

Minimum Order Quantity 1 Set

Price 6000 USD ($)/Piece

Standard Undriven Turks Head Wedge Wire Rolling Machine Product Specifications

Warranty 1 year

Computerized Yes

Automatic Grade Automatic

Capacity 5 Ton/day

Type Cold Rolling Mill

Voltage 380-440 Watt (w)

Material rolling from round wires into flat&shaped ss wire,carbon steel wire,alloy wire

Power 380 Watt (w)

Control System Frequency Speed Control

Standard Undriven Turks Head Wedge Wire Rolling Machine Trade Information

FOB Port shanghai

Payment Terms Letter of Credit (L/C)

Supply Ability 10 Set Per Year

Delivery Time 2 Week

Sample Policy Contact us for information regarding our sample policy

Main Export Market(s) Australia North America Eastern Europe Middle East Africa Central America South America Asia

Main Domestic Market Central India

Product Description

un-Driven turks head rolling machine

Flat Steel Rolling Mill Rolling Mill Spare Parts Manufacturers

Turks head assembly machine can roll from round wires to flat and shaped wire, ,wedge wires,triangular wires,square wires,Trapezoidal wires,Pentagonal wire,Hexagonal wire and etc.

Features: possibilty of roller non-replacing when forming profiled wires.

Uses: used for rolling flat wire, square wire, rectangular and other profiled wires.

Applying materials: suitable for high-carbon, medium-carbon, low-carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire, copper aluminum wire, brass wire and other non-ferrous and ferrous metals.

Roller material: the rollers are often chosen for their final products, such as tool steel, sintered metal or carbide steel.

Roll diameter: 75-350mm

Main power: servo motor or three-phase asynchronous motor

Press-down mode: electric or mnual

Optional devices: guide wire device, roll force measurement system, central lubrication system, etc.

Company introduction

our factory specialized in precision cold rolling mills and systems for metal shaping, which mainly products includes micro precision rolling mills, micro rolling cassettes, universal rolling mills, and precision rollers. We have independently R&D rectangular spring wire line, flat wire rolling mill, volute spiral spring continuous rolling line, valve spring shaped wire rolling mill, and triangular wire rolling mill to replace brand Europe/USA/Japan cold rolling mills. By the new method of Self-made rolling mill combined with rolling die, our concept will be adjusted to this new method it guarantees for the most cost-saving quality improvement of your products. better quality in evenness and finishing, the straightness up to 0.5mm/m, thickness and width tolerance can be accurate down to within 0.005mm.

Active introduction of Brand Japan micro high-precision roll processing and grinding technology, the roundness tolerance is less than 0.001mm., finishing is 0.02