What Types of Machinery Are Required to Manufacture Enameled Rectangular Copper Wire?

Addtime:2025-10-13View:226

Enameled rectangular copper wire is a vital component in modern electrical and industrial applications. From transformers and motors to electric vehicles and renewable energy systems, its superior conductivity, durability, and compact form factor make it essential for high-performance devices. But achieving consistent quality requires more than raw copper — it demands the right machinery. In this article, we explore the various types of equipment required to manufacture enameled rectangular copper wire, their functions, and why choosing the best manufacturer can make a significant difference in efficiency, product quality, and cost.

1. Understanding Enameled Rectangular Copper Wire

Before diving into machinery, it's essential to understand why rectangular copper wire is preferred in many applications. Unlike round wire, rectangular wire allows tighter winding and greater packing density in coils. This translates to:

Higher space efficiency in motors and transformers

Improved heat dissipation, extending device lifespan

Enhanced electrical performance due to uniform current distribution

To maintain these advantages, the production process must achieve precise dimensions, smooth surface finish, and uniform insulation. This is only possible with specialized machinery.

2. Wire Drawing Machines

The first stage in producing enameled rectangular copper wire is wire drawing. Copper rods are drawn through a series of dies to reduce their diameter while increasing their length. This step requires high-precision wire drawing machines, which ensure:

Consistent diameter

Smooth surface finish

Uniform mechanical properties

Modern wire drawing machines often integrate inline lubrication systems to reduce friction and wear, improving both efficiency and wire quality. Choosing a reliable manufacturer at this stage ensures minimal defects and higher yield, which directly affects the final product cost.

3. Annealing Furnaces

After drawing, the copper wire becomes harder and less ductile due to work hardening. To restore its flexibility, annealing is required. Annealing furnaces perform controlled heating to relieve internal stress and improve ductility. Key types of annealing equipment include:

Tubular annealing furnaces for small batches or low-volume production

Electric heating furnaces for precise temperature control

Inline annealing systems integrated with rolling or coating lines

Intermediate and final annealing steps are essential to prevent brittleness, avoid cracks during subsequent processing, and ensure the wire can withstand bending and winding in applications.

4. Rolling Mills

Transforming round copper wire into rectangular wire requires rolling mills, the core machinery of the process. Rolling mills apply controlled pressure using precision-engineered rollers to flatten the wire into the desired rectangular cross-section. Features of advanced rolling mills include:

Multiple rolling passes for gradual thickness reduction

Adjustable roll gaps to control final width and thickness

Edge control mechanisms to prevent burrs or deformation

Rolling mills designed specifically for rectangular wire are crucial for maintaining uniformity and surface quality. Selecting a high-quality manufacturer ensures consistent flatness and tolerance, which is critical for enameled wire performance.

5. Straightening Units

Before and after rolling, wires often need straightening. Copper wire can acquire bends or twists during drawing, coiling, or handling. Straightening units — typically Turkshead straighteners or multi-roller systems — remove these imperfections and ensure the wire:

Enters the rolling mill under uniform tension

Maintains dimensional accuracy

Avoids edge cracking and surface defects

Proper straightening is vital to produce high-quality rectangular wire and prevent waste or rework in later stages.

6. Insulation Coating (Enameled Wire Machines)

Once the wire has been shaped, it requires insulation for electrical applications. Enameled wire coating machines apply a thin, uniform layer of enamel or polymer to the copper surface. Key features of these machines include:

High-temperature curing ovens

Precision coating applicators for uniform thickness

Multi-layer insulation capabilities for high-voltage applications

The coating not only provides electrical insulation but also protects the wire from oxidation, corrosion, and mechanical wear. Using advanced enameled wire machines ensures reliable insulation and consistent quality.

7. Polishing and Cleaning Machines

Surface quality is critical for both electrical performance and enamel adhesion. Polishing and cleaning machines remove impurities, oxides, and surface irregularities before insulation. They can include:

Mechanical polishers to smooth wire surfaces

Chemical cleaning systems to remove oils and contaminants

Ultrasonic cleaning units for precision cleaning of fine wire

Integrating these machines with rolling lines improves product quality and reduces the risk of insulation defects.

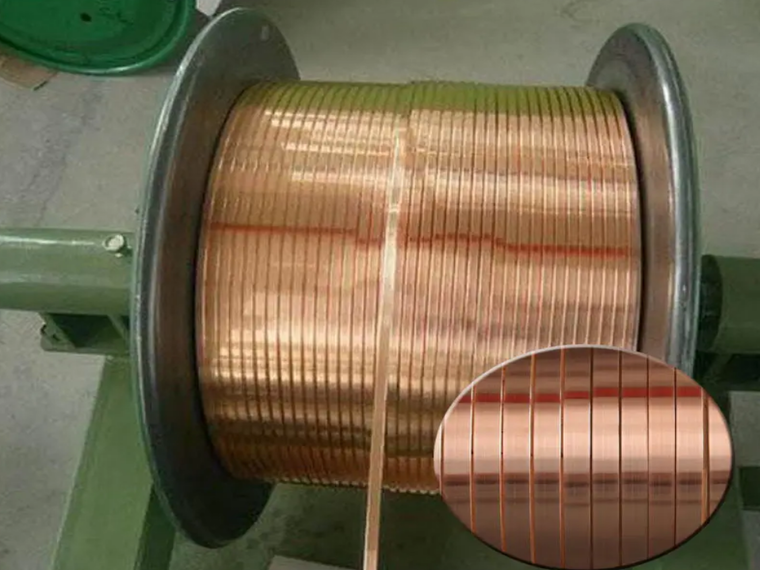

8. Take-Up and Coiling Systems

After coating and curing, the finished rectangular wire must be coiled and prepared for shipment. Take-up systems control tension and speed to ensure:

Uniform winding

Prevention of deformation or scratches

Ready-to-use coils for industrial applications

High-quality take-up units reduce handling damage and make subsequent use easier for manufacturers of motors, transformers, and other devices.

9. Quality Control and Testing Equipment

Producing enameled rectangular copper wire is not complete without rigorous quality control. Testing equipment monitors:

Wire dimensions and tolerances

Surface smoothness and enamel thickness

Electrical conductivity and insulation resistance

Mechanical strength and ductility

Investing in precise testing machinery ensures defects are caught early, reducing waste and maintaining high customer satisfaction.

10. Why Choosing the Best Manufacturer in China?

Selecting the right manufacturer for wire rolling and enameled wire machinery impacts both product quality and cost efficiency. A top-tier manufacturer ensures:

Cold Rolling Machines with high precision and long service life

Integration of multiple processes into turnkey solutions

Advanced technology for higher output and lower waste

Reliable after-sales support for maintenance and troubleshooting

11. Why Sky Bluer Environmental Technology Co., Ltd Leads the Industry Wire Flattening Mills?

For businesses looking for enameled rectangular copper wire equipment, Sky Bluer Environmental Technology Co., Ltd is a trusted partner. Based in China, Sky Bluer combines years of expertise with advanced engineering to provide:

Complete turnkey machine solutions for flat and enameled wire production line

High-precision wire drawing, rolling, annealing, polishing, and coating machines

Customized systems to meet unique production requirements

Competitive pricing without compromising quality

Sky Bluer’s commitment to innovation and customer support has made it one of the leading manufacturers of enameled rectangular copper wire equipment worldwide. By choosing Sky Bluer, companies gain a reliable partner that maximizes efficiency, minimizes defects, and ensures consistent high-quality output.

Conclusion

Manufacturing enameled rectangular copper wire requires a range of specialized rolling and drawing machinery, from wire drawing and annealing to rolling, straightening, polishing, coating, and take-up systems. Each piece of equipment plays a crucial role in achieving high-quality, dimensionally accurate wire suitable for modern electrical applications.

Partnering with the best manufacturer, like Sky Bluer Environmental Technology Co., Ltd, ensures seamless integration of machinery, precise control of production processes, and consistent product quality — all while optimizing cost and efficiency.With the right equipment and expertise, producing premium enameled rectangular copper wire becomes both efficient and reliable, meeting the demands of today’s high-performance electrical and industrial applications.