Cold Rolling Machine

High Precision 2 Hi Rolling Mill is suitable for high/medium/low carbon steel wire, stainless steel wire, titanium nickel alloy wire, titanium wire, copper aluminum wire, brass wire and varied other non-ferrous & ferrous.It is fitted with Aviation grade rollers, which are selected for the final products like tool steel, carbide steel or sintered metal. Owing to user-friendly control panel, it can easily be operated by single operator.Features: energy efficient, durable, rust proof and can be availed by clients in different models, and specifications.

Description

Cold Rolling Machine

Cold rolling machine for flat wire and square wire manufacturer | |

Brand | CRM |

Model | CRM-2024-89877 |

Line Speed | 30-350 m/Min |

Type | Precision Cold Rolling |

Input Material Details | |

Material Grade | Spring Steel Wires |

Input Diameter | Customized |

Tolerance | +-0.001mm or can be Customized |

Stages | Single stage/Tandem wire flattening& shaping lines |

Output Material Details | |

Shapes | Flat shapes, Deburred |

Output range | Thicknesses in mm, 0.15 – 8mm Width in mm, 1 – 30mm |

Finishes | Rolled, Annealed, Hardened and tempered |

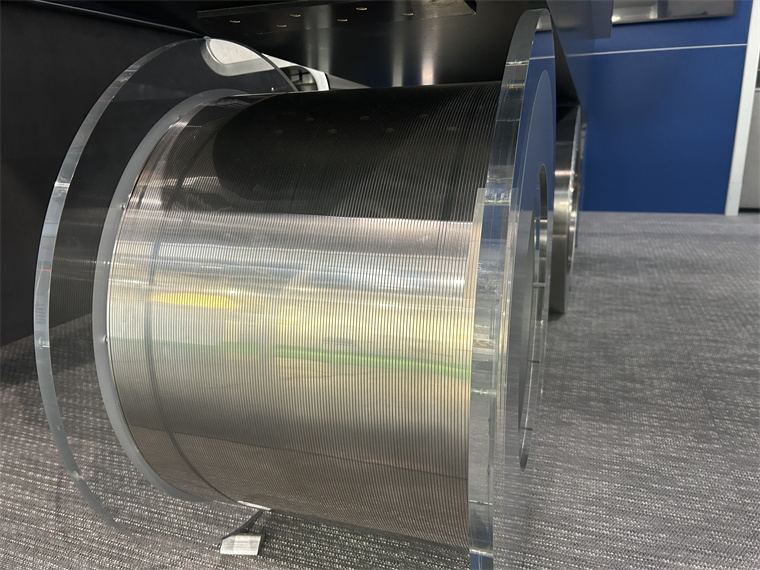

Wire Takeups | |

Widths | from 10mm |

Inner Diameter | 400-500mm |

Outer Diameter | max. 1,350 |

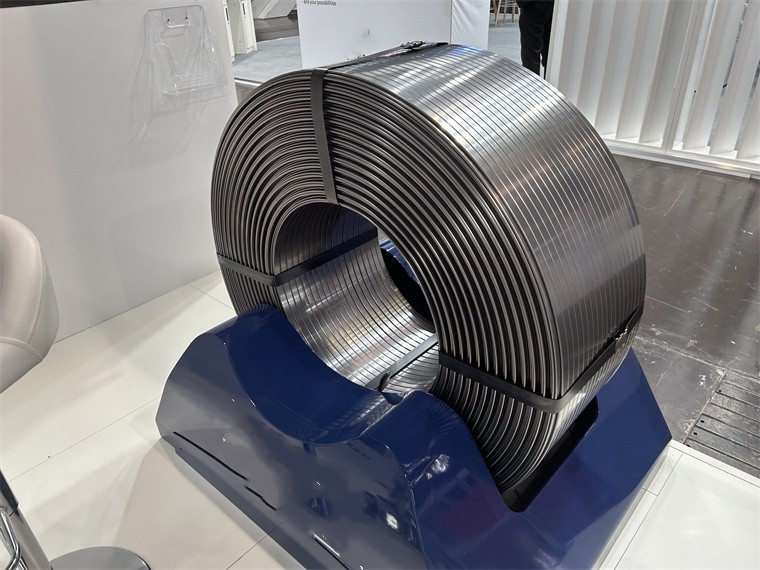

Oscillated Wound Coils | |

Inner Diameter | 400 – 500mm |

Outer Diameter | max. 1,200 |

Coil Width | 80 - 550 |

Coil Weight | max. 2,700 |

Product Details:

Type Cold Rolling Mill

Material ss wire,carbon steel wire,alloy wire

Capacity 5 Ton/day

Computerized Yes

Automatic Grade Semi-Automatic

Control System PLC Control

Voltage 380-440 Volt (v)

Cold Rolling Machine Price And Quantity

Minimum Order Quantity 1 Set

Price 3500 USD ($)/Set

Price Range 3500.00 - 6000.00 USD ($)/Set

Cold Rolling Machine Product Specifications

Control System PLC Control

Type Cold Rolling Mill

Warranty 1 year

Material ss wire,carbon steel wire,alloy wire

Computerized Yes

Capacity 5 Ton/day

Power 380-440 Volt (v)

Automatic Grade Semi-Automatic

Voltage 380-440 Volt (v)

Cold Rolling Machine Trade Information

FOB Port shanghai,China

Payment Terms Letter of Credit (L/C) Telegraphic Transfer (T/T)

Supply Ability 25 Set Per Year

Delivery Time 2 Months

Sample Policy Contact us for information regarding our sample policy

Main Export Market(s) Eastern Europe Middle East Western Europe South America North America Central America Africa Asia Australia

Product Description

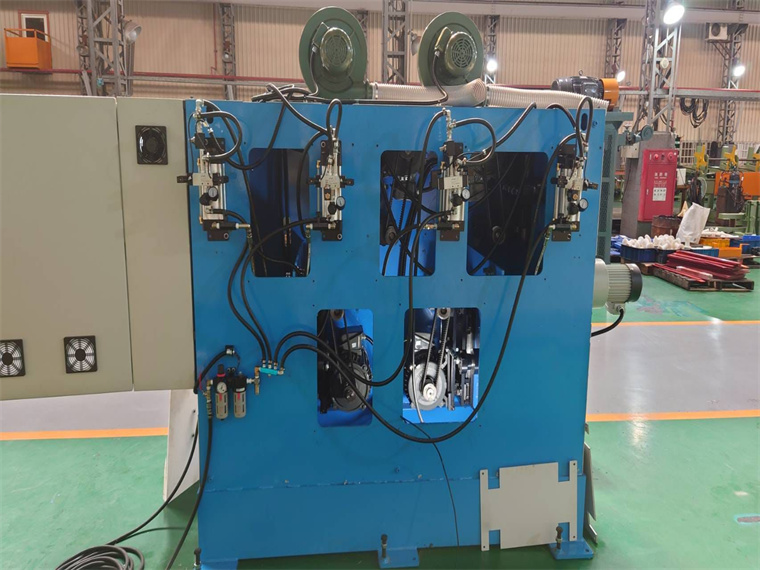

Cold Rolling Machine for rolling flat and square wires with high accuracy/2 Hi rolling mill/CRM 2 Hi cold rolling mill/Precision Two-High Rolling Mill/Z series wire rolling mill/Z series wire rolling machine

High Precision 2 Hi Rolling Mill is suitable for high/medium/low carbon steel wire, stainless steel wire, titanium nickel alloy wire, titanium wire, copper aluminum wire, brass wire and varied other non-ferrous & ferrous.

It is fitted with Aviation grade rollers, which are selected for the final products like tool steel, carbide steel or sintered metal. Owing to user-friendly control panel, it can easily be operated by single operator.

Features: energy efficient, durable, rust proof and can be availed by clients in different models, and specifications.

Description

Roll diameter: 90-350mm

Roll accuracy: Less than 0.001mm

Power system: Servo motor or three-phase motor

Press-down mode: Electric or Manual

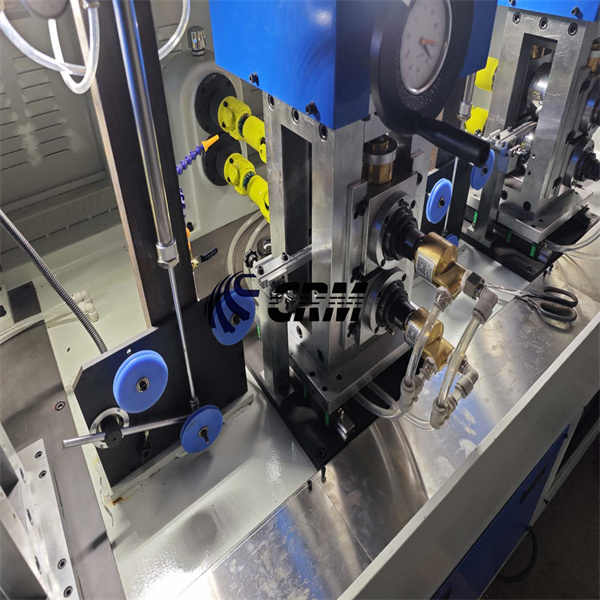

The parts of Machine

All the cold rolling machines from our factory has advanced technology and strong practicability, especially the universal rolling mill adopts German technology, which is well received by customers. All parts on the equipment have been processed internally by our company, which not only reduces the cost and ensures the quality, but also Shortened delivery time

About Company

Sky Bluer Environmental Technology Co. Ltd is manufacture specialized in high precision cold rolling mills , which mainly includes micro precision cold rolling mills, cassette roller dies, Turk heads, wire flattening mills, strips rolling mill,universal rolling mills, and precision rolling mill rollers for flat and shaped wires.

By the new method of Self-made cold rolling mill combined with drawing rolling die, our concept will be adjusted to this new method it guarantees for the most cost-saving quality improvement of your products. better quality in evenness and finishing, the straightness up to 0.5mm/m, thickness and width tolerance can be accurate down to within 0.005mm. Active introduction of Brand Japan small high-precision roll processing and grinding technology, the roundness tolerance is less than 0.001mm., finishing is 0.02.

Service Commitment: What we provide is not only equipment, but also technology and service. We provide users with free-of-charge for shaped wire proofing and hole design.