Precision Rolling Mills

The precision rolling process includes mold making, bar heating, finishing rolling forming, finishing straightening and other processes. Compared with the existing cross wedge rolling rough rolling technology, the material saving rate is increased by more than 10%, and the comprehensive mechanical properties of parts are increased by more than 5%. The tolerance zone of the finished product rolled out by precision rolling is about 1/2 smaller than the high-precision tolerance of the international standard. The rolled bar and wire can be directly ground without drawing or cutting. Therefore, the demand for precision rolled steel is increasing year by year, especially for some high-grade alloy steels, the cost of raw materials is high, and precision rolling has its special significance

Description

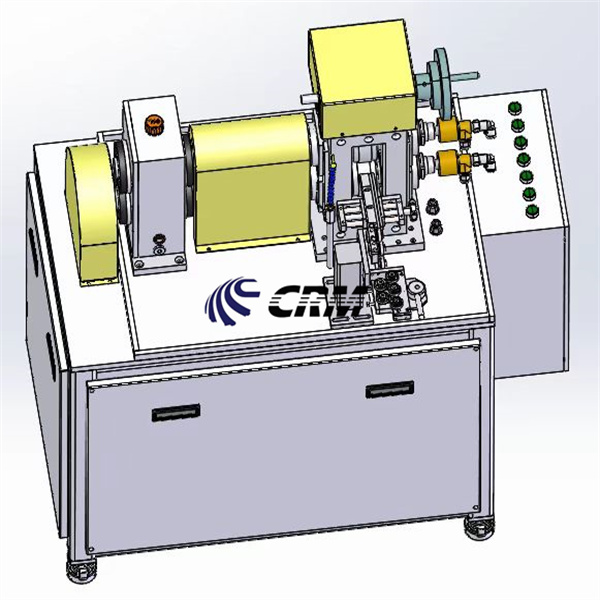

Precision Rolling Mills

Product Details:

Material Stainless steel 304, 304L, 316, 316L, or as your need

Share Your Product:

precision rolling mills Price And Quantity

Minimum Order Quantity 1 Set

Price Range 1.00 - 2.00 USD ($)/Set

Price 1.0 USD ($)/Set

precision rolling mills Product Specifications

Material Stainless steel 304, 304L, 316, 316L, or as your need

precision rolling mills Trade Information

FOB Port shanghai,China

Supply Ability 10 Set Per Month

Delivery Time 50 Days

Sample Policy Contact us for information regarding our sample policy

Certifications ISO,CE,

Product Description

Precision rolling mills/Profile rolling mills

shapes:flat.rectangle,square

Material: Stainless steel 304, 304L, 316, 316L, or as your need

shapes:round,rectangle,rectangular,flat,square,wedge,oval,special-shaped

Length/Width: Customized on demand

Minimum slot size: 20

Minimum slot size: 20

Thickness: Customized on demand

Filter form: Surface filtration

The wedge wire screen panel is an important working part of the screening machine to complete the screening process. Each screening machine must select a sieve plate that meets its working requirements. The various characteristics of the material, the different structures of the sieve plate, the material, and the various parameters of the sieve machine have a certain influence on the screening ability, efficiency, running rate, and life of the vibrating screen.

Different materials and different places should use different sieve plates to achieve the best effect of screening. The sieve plate should have sufficient strength, a high opening ratio, and difficulty in plugging holes. When the vibrating screen vibrates, the wedge wire sieve plate passes through materials of different shapes and sizes, material size, and under the action of vibration force, the materials of different particle sizes are separated to achieve the purpose of classification.

The precision rolling process includes mold making, bar heating, finishing rolling forming, finishing straightening and other processes. Compared with the existing cross wedge rolling rough rolling technology, the material saving rate is increased by more than 10%, and the comprehensive mechanical properties of parts are increased by more than 5%. The tolerance zone of the finished product rolled out by precision rolling is about 1/2 smaller than the high-precision tolerance of the international standard. The rolled bar and wire can be directly ground without drawing or cutting. Therefore, the demand for precision rolled steel is increasing year by year, especially for some high-grade alloy steels, the cost of raw materials is high, and precision rolling has its special significance

The precision rolling process includes mold making, bar heating, finishing rolling forming, finishing straightening and other processes. Compared with the existing cross wedge rolling rough rolling technology, the material saving rate is increased by more than 10%, and the comprehensive mechanical properties of parts are increased by more than 5%. The tolerance zone of the finished product rolled out by precision rolling is about 1/2 smaller than the high-precision tolerance of the international standard. The rolled bar and wire can be directly ground without drawing or cutting. Therefore, the demand for precision rolled steel is increasing year by year, especially for some high-grade alloy steels, the cost of raw materials is high, and precision rolling has its special significance