Stainless Steel Square Wire Production Lines

we are the leading manufacturer of square wire rolling mill production lines and wire drawing machine production lines. In this article, we will walk you through the process of using our CRM2025-SS machine model to produce stainless steel square wire. We hope this article provides you with a deeper understanding of the square wire production process.

Description

How Is Stainless Steel Square Wire Produced?

First, we would like to highlight that we are the leading manufacturer of square wire rolling mill production lines and wire drawing machine production lines. In this article, we will walk you through the process of using our CRM2025-SS machine model to produce stainless steel square wire. We hope this article provides you with a deeper understanding of the square wire production process.

Main Specifications for Stainless Steel Square Wire Equipment

• Input Material: Round wire / Round bar

• Output Material: Square wire

• Line Speed: 350 m/min

• Tolerance: ±0.001 mm

• Forming Method: Cold wire forming

• Round Wire Provision: Supplied in bundles

• Square Wire Packing: Square wire wound as a coil, with tightly wound turns neatly layered

• Purpose: To produce square wire from round wire

• Production Line Composition:

o Wire payoff

o Straightening machine

o Tension control

o Rolling mills

o Polishing unit

o Wire take-ups

What Are the Main Features of the CRM2025 Square Wire Production Line?

What Is The Production Process Of Stainless Steel Square Wire?

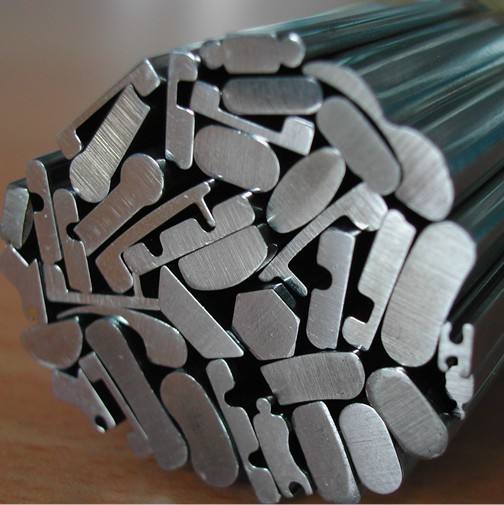

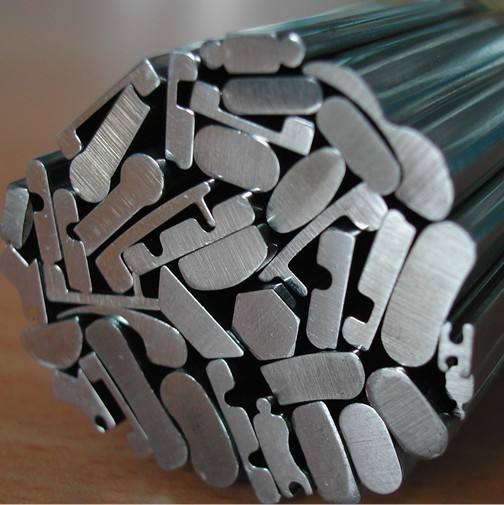

The process of producing stainless steel square wire from round wire involves several key steps. First, high-quality stainless steel round wire is selected, typically made from alloys such as 301, 302, 304/304L, 304V, 316L, 410, 416, 420, 17-7PH, and more. It is then drawn to reduce its diameter for consistency, with the number of drawing blocks depending on the desired size of the square wire. Next, the wire is passed through specially designed tungsten carbide rollers to shape it into a square cross-section. After forming, the wire undergoes annealing to relieve internal stress and enhance ductility. Surface treatments, including straightening, cleaning, polishing, and coating, are applied to achieve a smooth finish. The wire is then tested for dimensional accuracy and mechanical properties using a inline laser gauge to ensure it meets industry standards. Finally, the finished square wire is produced.

What Other Materials Can This Equipment Handle Besides Stainless Steel Square Wire?

• Nickel Alloy Square Wire: Compatible with materials such as Monel 400, Monel 405, Inconel 600, Inconel 625, X750, and more.

• Carbon Steel Square Wire: Suitable for processing Music Wire, Galvanized Wire, HDMB, OTMB, Chrome Silicon, Chrome Vanadium, 1050, 1075, 1095, and beyond.

• Red Metals: Handles materials like Beryllium Copper, Phosphor Bronze, and more.

• Precious Metal Square Wire: Primarily includes gold, silver, platinum, and platinum group metals such as ruthenium, rhodium, palladium, osmium, and iridium

Applications of Stainless Steel Square Wire Production Lines

Stainless steel square wire is a highly versatile material, valued for its durability, corrosion resistance, and precise geometry. It is widely used across numerous industries, including:

1. Construction and Architecture:Ideal for structural components, reinforcements, and decorative elements such as grills, screens, and railings.

2. Automotive Industry:Used to manufacture springs, fasteners, and other precision parts critical for vehicle performance.

3. Medical Devices:Frequently applied in surgical instruments, orthodontic wires, and implants due to its biocompatibility and strength. It also includes surgical wires for medical operations, which are very common in hospitals.

4. Electronics:Integral for connectors, leads, and precision components in electronic devices and circuits. For example, the special cable industry used in the military has extremely high requirements for precision and square wire.

5. Jewelry and Crafts:Popular for creating frames, clasps, and intricate designs in jewelry, thanks to its strength and visual appeal. This is mainly applied to some areas of precious metals

6. Aerospace Industry:Used in high-performance components requiring exceptional strength and resistance to extreme conditions. For example, components and parts for aircraft manufacturing, high-precision aerospace products, etc.

7. Industrial Applications:Very suitable for industries such as petroleum, chemical and mining, Essential for filtration systems, sieves, and conveyor belts in manufacturing and processing facilities.

8. Marine Equipment:Perfect for marine cables, fittings, and other applications demanding excellent corrosion resistance.

So we know Stainless steel square wire is an indispensable material in industries where precision, durability, and reliability are paramount.

CRM Precision Rolling Mills: Custom Solutions for Diverse Applications

CRM designs and manufactures a comprehensive range of precision rolling mills, offering both standard and customized solutions for a variety of applications. These include heavy ingot crushing, laboratory research, small-scale precision mills, roll-to-roll rolling, and precision strip production.

Our mills are available in 2Hi and 4Hi roll configurations, with options for work roll-driven, support roll-driven, or a combination of both.

• 4Hi Rolling Mill: Features a working roll diameter as small as 0.500 inches (12.7 mm). We offer both standard and custom-designed four-roll mills, including active and passive configurations to meet specific needs.

• 2Hi Rolling Mill: Supports roll diameters up to 16 inches (400 mm). Roll materials can be tailored to your requirements, with options such as tungsten steel or tool steel for enhanced durability and performance.

• Turnkey Projects:One of our key advantages is providing turnkey solutions, delivering a seamless, one-stop service. From initial design to installation and operation, we ensure a hassle-free experience tailored to your needs.CRM's expertise ensures precision, efficiency, and reliability for all your metal rolling applications.

About company

Sky Bluer Environmental Technology Co., Ltd. specializes in manufacturing precision cold rolling mills and metal shaping systems. Our product lineup includes micro-precision cold wire flattening and shaping lines, rolling cassettes, Turk heads, universal rolling mills, and precision rollers. We have independently developed various advanced systems, such as rectangular spring wire rolling mills, flat wire rolling mills, volute spiral spring continuous rolling lines, valve spring rolling mills, and triangular wire rolling mills, offering cost-effective alternatives to European, American, and Japanese cold rolling mills.

By combining our self-designed cold rolling mills with drawing rolling dies, we provide an innovative method to enhance your product quality while reducing costs. This approach ensures superior evenness and finishing, with straightness up to 0.5mm/m and thickness and width tolerances as precise as ±0.005mm.

Furthermore, we actively integrate advanced Japanese small high-precision roll processing and grinding technologies, achieving a roundness tolerance of less than 0.001mm and a surface finish of 0.02μm. Sky Bluer is committed to delivering exceptional performance and precision for all your metal shaping needs.