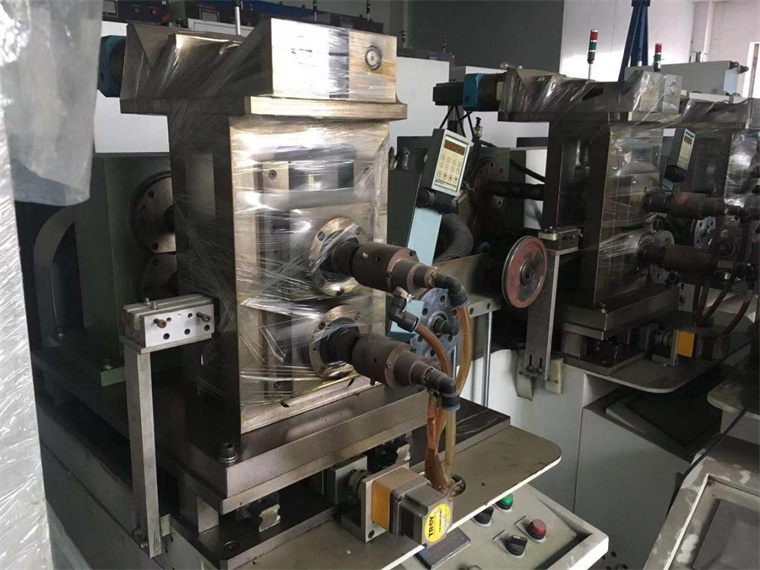

Wire Flattening Machine

This equipment is a cold rolling mill specifically designed for processing round wire into flat wire through a precision cold rolling process. It is suitable for a variety of non-ferrous metals, including copper, brass, aluminum, and stainless steel,carbon steel, Titanium wire, titanium alloy

Description

This equipment is a cold rolling mill specifically designed for processing round wire into flat wire through a precision cold rolling process. It is suitable for a variety of non-ferrous metals, including copper, brass, aluminum, and stainless steel,carbon steel, Titanium wire, titanium alloy

Wire flattener size range

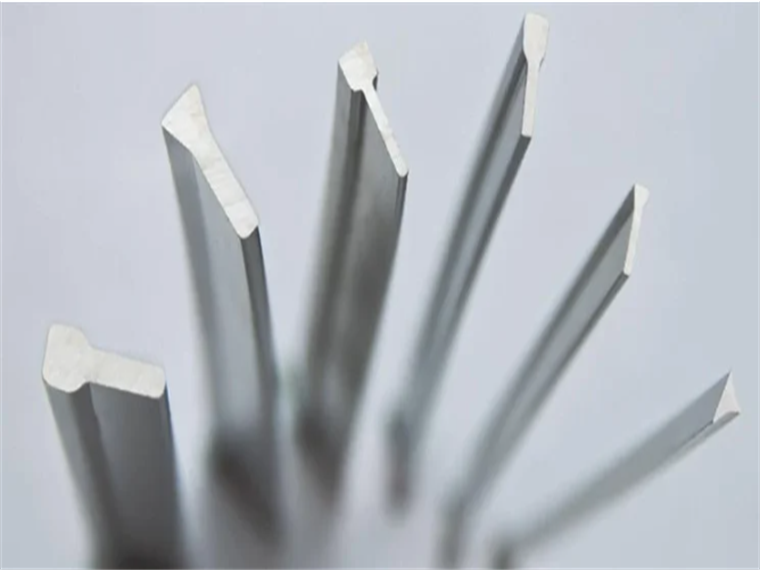

The typical input material is round wire with diameters ranging from Ø1.0 mm to Ø6.0 mm, which can be processed into flat wire with widths from 1.5 mm to 20 mm and thicknesses down to 0.10 mm, depending on the configuration and pass schedule.

This system ensures tight dimensional tolerances, excellent surface finish, and is ideal for applications requiring high-precision flat wire profiles.

Flattening copper wire

Size Range

1. Application: Rolling and drawing round wire into arc copper flat wire

2. Production Line Speed: Up to 250 m/min

3. Maximum Input Wire Size: 12.5 mm

4. Finished Product Dimensions:

- Narrow side thickness (A): 0.9 mm to 3.5 mm

- Wide side width (B): 3.0 mm to 14.0 mm

Wire Flattening Mill Machine Manufacturer, Stainless Steel

Copper Wire Flattening Process

Flattening copper or brass wire is a high-precision cold rolling operation that reshapes round wire into flat or profiled cross-sections. This process is carried out using a CRM cold rolling mill system, known for its accuracy and reliability in non-ferrous metal processing.

A standard flattening line typically consists of the following equipment:

• 2-Hi Rolling Mill – Performs initial thickness reduction and surface refinement.

• Turks Head Profile Rolling Mill – Shapes the wire into specific profiles with tight dimensional control.

• Flat Wire Drawing Machine – Further reduces wire dimensions while improving mechanical properties and surface finish.

This configuration enables continuous production of high-quality flat wire with consistent width, thickness, and profile precision—suitable for demanding applications in electrical, automotive, and electronics industries.

Steel Wire Flattening Process

Our cold rolling process rolls round wire into flat or rectangular shapes. It processes a wide range of materials, including iron, stainless steel, carbon steel, DC01, and more. As a manufacturer of precision rolling mills, we equip our machines with programmable controllers that automate operations. These controllers actively monitor the locking status to ensure operator safety and prevent potential damage to rolling mill components.