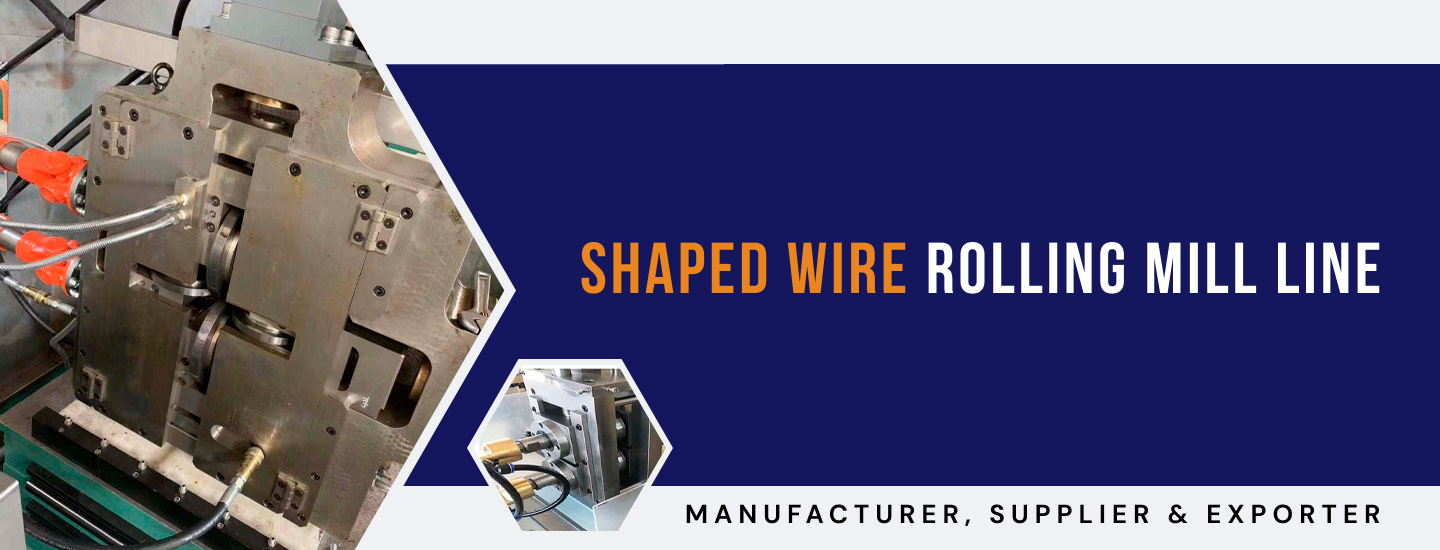

Company Profile

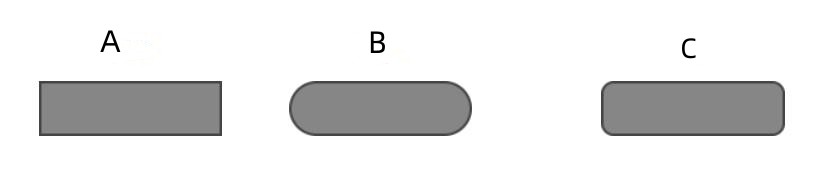

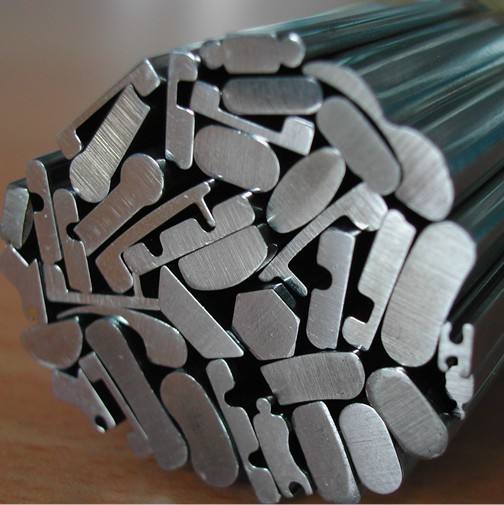

Founded in 2016, Sky Bluer Environmental Technology Co., Ltd. manufactures a variety shapes of industrial wire rolling lines, drawing lines, includes wire flattening mills, 2 Hi and 4 Hi rolling mills, universal rolling mills, PV ribbon lines, cold rolling cassettes, and precision rolls. As a replacement for cold rolling mills originating in Europe, America, and Japan, the company conducts independent research and development on rolling lines for spring steel square wire, flat wire, spring wire, shaped steel wire, wedge profile wire, and so forth. With the combination of modern technology and self-made rolling and drawing, the cost of grooving and the production of shaped wires can be greatly reduced. the rolled products are highly polished, with a straightness of up to 0.5mm/m, a thickness tolerance of less than 0.005mm, and a width tolerance less than 0.005mm.

Applications

1、Clutches

2、Coal Washing Screen

3、Die Springs

4、Engine Piston Rings

5、Environmental Protection Engineering

6、Glasses Parts

7、Handlebars

Product Center

-

Stainless Steel Square Wire Production Lines

we are the leading manufacturer of square wire rolling mill production lines and wire drawing machine production lines. In this article, we will walk you through the process of using our CRM2025-SS machine model to produce stainless steel square wire. We hope this article provides you with a deeper understanding of the square wire production process.

view more >>

-

Wire Flattening Machine

This equipment is a cold rolling mill specifically designed for processing round wire into flat wire through a precision cold rolling process. It is suitable for a variety of non-ferrous metals, including copper, brass, aluminum, and stainless steel,carbon steel, Titanium wire, titanium alloy

view more >>

-

GLWC-170 Cold Rolling Dies For Flat Wires

Sky Bluer Environmental Technology Co. Ltd is manufacture specialized in highprecision cold rolling mills and systems for metal shaping, which mainlyincludes micro precision cold rolling mills, cassette roller dies, Turks headdies, Turk heads, wire flattening mills, universal rolling mills, and precisionrolling mill rollers for flat and shaped wires. We have independently R&Drectangular spring wire mill, flat wire rolling mill, volute spiral springtandem rolling mill line, valve spring rolling mill, and triangular wirerolling mill to replace brand Europe/USA/Japan cold rolling mills.

By the new method of Self-made cold rolling mill combined with drawing rollingdie, our concept will be adjusted to this new method it guarantees for the mostcost-saving quality improvement ofyour products. better quality in evenness andfinishing, the straightness up to0.5mm/m, thickness and width tolerance can beaccurate down to within 0.005 mm. Active introduction of Brand Japan smallhigh-precision roll processing and grinding technology, the roundness toleranceis less than 0.001mm., finishing is 0.02.view more >>

-

Strip Rolling Machine

The purpose of the flat strip cold rolling mill is to reduce the thickness of the steel to the customer's specifications.The hot roll band passes back and forth between the rolls until it reaches the specified thickness. Like the pickle line, the cold rolling mill is able to handle two coils at a time. One coil lies in wait while the other is being processed.

view more >>

-

Best Wire Flattening Mill

Best wire flattening mill as knowns as wire flattening machine for flat wire rolling mill,the main model We Have Non-Standard 2 Hi Rolling Mill. There Are Specially Designed Ones That Are Used With Other Machines ,Such As Making Barrette With Wire Bending Machine, Making Floral-Pattern Metal Chain With Chain Weaving Machine, Making Flat Wire Steel Prop With Spring Machine, Because Of A Wide Variety Of 2 Hi Rolling Mill We Don't List Here One By One, And It Also Can Be Customized According To The Sample.

view more >>

-

Gz300 2 Hi Cold Rolling Mill For Flat And Shaped Wires

We are supplying here the high quality High Precision 2 Hi Rolling Mill consisting of two rolls or known as a 2 High rolling mill is used for anything from temper pass to breakdown of material. The 2 High rolling mills typically have larger diameter work rolls that are positioned with actuators. In the High Precision 2 hi rolling mills, the entire roll diameter is relatively large, and the area of contact with the tie pieces is also very large, so the overall rolling force is relatively large, so the material for rolling. They are very efficient and easy to operate.

view more >>

-

Wire Flattening Machine

copper Strip Rolling Mill,copper rolling mill,copper Strip Rolling Mill factory,copper and brass Strip Rolling Mill manufacturer,copper wire Strip Rolling Mill price,Strip Rolling Mill china,Strip Rolling Mill germany,Strip Rolling Mill machine,Strip Rolling Mill UK

view more >>

SKY BLUER ENVIRONMENTAL TECHNOLOGY CO.,LTD.

Founded in 2016, Sky Bluer Environmental Technology Co., Ltd. manufactures a variety shapes of industrial wire rolling lines, drawing lines, includes wire flattening mills, 2 Hi and 4 Hi rolling mills, universal rolling mills, PV ribbon lines, cold rolling cassettes, and precision rolls. As a replacement for cold rolling mills originating in Europe, America, and Japan, the company conducts independent research and development on rolling lines for spring steel square wire, flat wire, spring wire, shaped steel wire, wedge profile wire,Straight forward wire drawing machine and so forth. With the combination of modern technology and self-made rolling and drawing, the cost of grooving and the production of shaped wires can be greatly reduced. the rolled products are highly polished, with a straightness of up to 0.5mm/m, a thickness tolerance of less than 0.005mm, and a width tolerance less than 0.005mm.

View More >>News Center

-

10-13

2025

What Types of Machinery Are Required to Manufacture Enameled Rectangular Copper Wire?

Enameled rectangular copper wire is a vital component in modern electrical and industrial applications. From transformers and motors to electric vehicles and renewable energy systems, its superior conductivity, durability, and compact form factor make it essential for high-performance devices. But achieving consistent quality requires more than raw copper — it demands the right machinery. In this article, we explore the various types of equipment required to manufacture enameled rectangular copper wire, their functions, and why choosing the best manufacturer can make a significant difference in efficiency, product quality, and cost.

-

10-01

2025

Which Equipment Converts Round Wire into Flat Wire?

At Sky Bluer Environmental Technology Co., Ltd, we specialise in designing and building the best wire flattening and shaping machines. We actively work with clients to match them with the right solution, whether they run small workshops or large industrial plants.

-

09-29

2025

Oil-Tempered Flat Wire Production Line: Best Manufacturer, Supplier, and Price in China

Oil-tempered flat wire has become indispensable in modern industry. Whether it is used in automotive suspension systems, agricultural tools, or construction equipment, this material combines durability with precision performance. Companies that depend on strong and reliable flat wire are now paying closer attention to the production process and the choice of the right manufacturer or supplier. For many buyers, China remains the most attractive source because of its technology, production scale, and competitive price advantage.

-

09-18

2025

Application of Enameled Flat Wire Equipment

Enameled flat wire has become a game-changer in industries ranging from electric vehicles to industrial machinery. Its unique flat or rectangular profile, combined with a durable enamel coating, allows for tighter winding in motors, better space utilisation, and superior heat management. This means your machines can run cooler, more efficiently, and with higher performance.

-

Factory Location

Based in Zhangjiagang city, Jiangsu, China, we have network all over the world for supplying high precision machinery and rolling cassettes.

-

Equipment

CRM machines are specially tailored to your application. our wide product range always enables the most suitable solution for the highest wire precision and quality. The High precision machines impress with their high level of reliability and low maintenance costs.

-

Custom Engineered Solutions

We are Design-to-Build, with the entire process being conducted under one roof,We are proud to continue offering prompt customer service and support after the sale of every machine

-

After-sales Service

CRM’s experienced engineers are on call to ensure minimal downtime and the highest levels of productivity for your equipment